Features

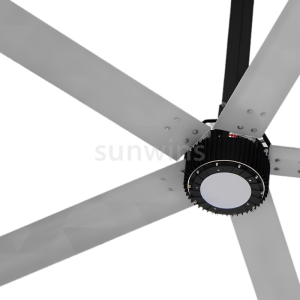

Blade Design

Using high quality aluminium magnesium alloy, more than 20 years with corrosion resistance, high strength, high toughness, fatigue resistance, bright surface oxidation treatment, easy to clean. The use of advanced fluid dynamics simulation software CFD modelling and wind tunnel testing , aerodynamic shape with a unique anti-fatigue lined design.

Safety Protection

Multiple security anti-drop protection ring design of annular fan chain secure connection, which are connected into a whole, guarantee stability of each system connection and prevent blade drop alone. The HVLS Fans can be in a fixed position with 2 pieces wire rope upon the motor frame, 4 pieces wire rope be tensed towards 4 direction below the motor frame, to prevent rotation shaking in large inertia, to guarantee versatility stability and security. Design of annular fan chain around fan blade, which are connected into a whole, guarantee fastness of fan blade as well as drop alone. HVLS Fans uses high strength bolts made of 30CrMnSi material, level 12.9, and using the thread fastening agent, to prevent loosening. Firm electric control system.

Energy Saving

HLVS fans can help save costs in many ways. Its low energy consumption powertrain saves you money by being energy-efficient. With its effective air disbursement, HVLS fans are a cost effective and ideal solution for cooling large facilities; as a standalone system or with air conditioning. When used together with an air conditioning system, the fan’s slow and steady airflow can reduce or even completely eliminate the need for costly and inefficient air conditioning ductwork.

IF energy charge for 1 KW/ h is RM 0.435, comparison for energy consumption and cost according to 12000m2 of ware house:

Project Capacity

(84 USRT)

Total Power Expenses per Month

(8 hours X 26 days) = 208 hours

Central air cond. 3000kw at 250 w/m3 960KW RM 86,860.00

Industrial Fans 200 sets / 500 watts 100Kw RM 9,048.00

HVLS Fans 8 sets / 1.5 Kw 12 Kw RM 1,085.75

External Load-bearing

Our industrial HVLS Fans are different from other manufacturers for that double external load bearing designed by ourselves, and extend oriented distance of fan, avoid reducer from axial force, prevent oil spilling and to extend the service life.

The Installation

- Installation on H Beam or I Beam structure steel: using pressing plate of 8mm thickness to fix.

- Fixing on steel concreate beam: using 8 mm stickiness 90 degree, using the wearing screw or expansion screw, fixing both right or left.

- The fixing of grid structure: using v structure or semi-circle to hoop bolts tensioned.